Rail Active Crossing System (RAXS) is a game changing level crossing protection system designed for rural and remote areas.

Rail Active Crossing System (RAXS) is a game changing level crossing protection system designed for rural and remote areas.

Many current crossings are incompatible with zero harm legislative requirements

Fast Regional Train program is impossible due to the large number of unprotected crossings

High social and economic cost of rail crossing fatalities– e.g Kerang Disaster 11 deaths, 14 injuries $14m cost

Replacement active crossing systems are expensive and slow to commission

Complete solution – High Visibility Fail-to-Safe Signage, Train Detection, Remote Crossing Management System

Compliant with relevant rail standards

Solar/wireless technology – dramatically cuts installation costs and time (over 50% cost saving)

Significant safety improvement makes RAXS compatible with zero harm rail legislation and fast train initiatives

Many current crossings are incompatible with zero harm legislative requirements

Fast Regional Train program is impossible due to the large number of unprotected crossings

High social and economic cost of rail crossing fatalities– e.g Kerang Disaster 11 deaths, 14 injuries $14m cost

Replacement active crossing systems are expensive and slow to commission

Complete solution – High Visibility Fail-to-Safe Signage, Train Detection, Remote Crossing Management System

Compliant with relevant rail standards

Solar/wireless technology – dramatically cuts installation costs and time (over 50% cost saving)

Significant safety improvement makes RAXS compatible with zero harm rail legislation and fast train initiatives

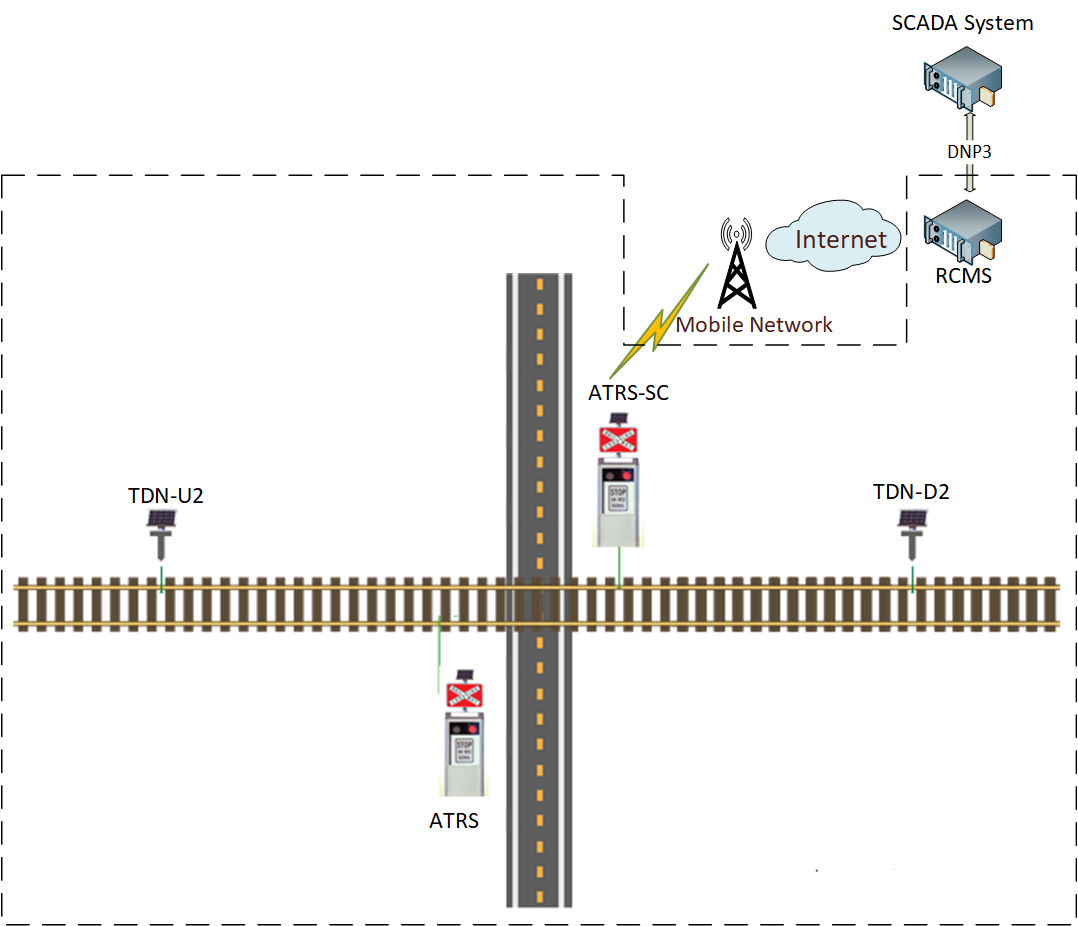

RAXS features a railway active signage system together with a train detection system.

Our product offers significant differentiation compared to conventional active or passive level crossing warning systems. Safe, clear, compliant regulatory signs provide unambiguous visual warnings to road users at all times; regardless of whether the crossing system is active or failed.

The RAXS design incorporates a true FailSafe to ensure the level crossing remains protected, even where there is a system failure or outage. Maintaining level crossing protection during failure or outage is particularly important for rural and remote level crossings where geographical isolation can mean delays in maintenance response times.

RAXS is autonomous, solar powered and wireless, ensuring faster and cheaper installation and lower operating costs. The system does not require external power or track-side cabling, reducing time, cost and risk, and reducing whole-of-life costs.

The Benefits of RAXS

Benefit

Benefit

Benefit

Benefit

Benefit

Reduces civil engineering costs and time to install a new level crossing protection system.

All major components (ATRS, AEWS, TDN) require strong stable footings – traditionally concrete was used. In remote rural locations the cost of digging the holes, freighting the materials (cement, water etc.), waiting for the footings to set etc. is significant.

RAXS uses an innovative technology called “Surefoot” to reduce these costs. Engineered to site conditions. Surefoot uses treated steel piles jack-hammered into the ground to create a highly stable platform.

Instead of taking many days to establish the footings – they can now be done in hours. The materials that need to be shipped to site are greatly reduced. The need for excavation equipment is removed. Labour costs are reduced.

Reduces the risk death and serious injury to road users and reduces the cost of deployment by excluding guard rails.

• The primary objectives of the crossing are to protect users from impact with trains and to reduce the risk to the road user if impact with the crossing infrastructure occurs.

• The road side structure (track side signage and early warning signs) are designed to reduce the risk to road users.

• They have been designed to be as light weight and energy absorbing as far as is reasonably practical.

• Through this innovative design roadside crash protection barriers have been made redundant.

• The road signage infrastructure has been crash tested at 100kph and 50kph.

Benefit

Enables road traffic to cross the rail corridor safely under a conventional Stop Sign operation.

Deters bad driver behavior due to continuous red flashing lights for extended periods.

Incorporates a patented fail-to-safe technology that presents a traditional STOP sign – if a critical failure is detected or if the system loses all power.

The fail-to-safe applies to both track side signs (a STOP sign) and to early warning signs (STOP Sign Ahead).

Based on feedback from a Rail CRC Study and DTMR, the fail-to-safe sign now incorporates flashing LED strips to maximise recognition of the changed signage.

This concept of an active/passive sign is highly innovative and with the assistance of DTMR has now resulted in changes to the MUTCD standard.

Benefit

A remote monitoring capability (RCMS) provides extensive statistics to maximise the effectiveness of maintenance visits – in terms of spares needed and activities required.

Monitoring information on solar / battery performance provides guidance on the need (or otherwise) to proactively replace batteries. Wireless performance levels can be evaluated. System alarms can be monitored 24/7.

Maintenance will typically involve: exercising the fail to safe functionality; cleaning the signage / solar panels; vegetation clearance, key switch operation, inspection of the wheel detection systems etc. and general system operation on site.

Training / Service Manuals provided by RSS to the operator’s personnel on system maintenance.

Only 1-2 service visits are required per year.

Benefit

Benefit

Benefit

Benefit

Benefit

Reduces civil engineering costs and time to install a new level crossing protection system.

All major components (ATRS, AEWS, TDN) require strong stable footings – traditionally concrete was used. In remote rural locations the cost of digging the holes, freighting the materials (cement, water etc.), waiting for the footings to set etc. is significant.

RAXS uses an innovative technology called “Surefoot” to reduce these costs. Engineered to site conditions. Surefoot uses treated steel piles jack-hammered into the ground to create a highly stable platform.

Instead of taking many days to establish the footings – they can now be done in hours. The materials that need to be shipped to site are greatly reduced. The need for excavation equipment is removed. Labour costs are reduced.

Benefit

Enables road traffic to cross the rail corridor safely under a conventional Stop Sign operation.

Deters bad driver behavior due to continuous red flashing lights for extended periods.

Incorporates a patented fail-to-safe technology that presents a traditional STOP sign – if a critical failure is detected or if the system loses all power.

The fail-to-safe applies to both track side signs (a STOP sign) and to early warning signs (STOP Sign Ahead).

Based on feedback from a Rail CRC Study and DTMR, the fail-to-safe sign now incorporates flashing LED strips to maximise recognition of the changed signage.

This concept of an active/passive sign is highly innovative and with the assistance of DTMR has now resulted in changes to the MUTCD standard.

Benefit

A remote monitoring capability (RCMS) provides extensive statistics to maximise the effectiveness of maintenance visits – in terms of spares needed and activities required.

Monitoring information on solar / battery performance provides guidance on the need (or otherwise) to proactively replace batteries. Wireless performance levels can be evaluated. System alarms can be monitored 24/7.

Maintenance will typically involve: exercising the fail to safe functionality; cleaning the signage / solar panels; vegetation clearance, key switch operation, inspection of the wheel detection systems etc. and general system operation on site.

Training / Service Manuals provided by RSS to the operator’s personnel on system maintenance.

Only 1-2 service visits are required per year.

Advantages

The RAXS signage sub-system and train detection system is particularly suited to regional rail level crossings, with the operating system also offering broad application to a variety of related safety solutions. RAXS has a number of advantages over traditional active rail crossing systems.

Advantages

The RAXS signage sub-system and train detection system is particularly suited to regional rail level crossings, with the operating system also offering broad application to a variety of related safety solutions. RAXS has a number of advantages over traditional active rail crossing systems.

RAXS Features and Innovation

A typical level crossing active protection upgrade requires significant resources to undertake signal design,electrical wiring and site construction to enable train detection and activation of the road traffic control measures. RAXS system incorporates new technology that reduces the overall costs in design, construction,monitoring and maintenance.

Train Detection Nodes (TDN) combined with axle counter technology to activate the crossing flash lights.

At Track Road Signs (ATRS) provide a LED flashinglight warning to motorists that a train is approaching the crossing. The signage also provides a fail to safe “STOP SIGN” mode in the event of a system disruption.

Active Early Warning Sign (AEWS) provide earlyindication to the motorist that a train is approaching the crossing and that flashing lights will soon start flashing ahead.

17-19 Edison Rd Dandenong South Victoria 3175

+61 3 9999 2740

info@railsafetysystems.com.au

Unit A7, 2A Westall Road Clayton VIC Australia 3168

+61 3 9999 2740

info@railsafetysystems.com.au